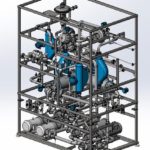

CPS developed and delivered a fully functioning and tested automation solution utilized in the distribution of Water-For-Injection (WFI) at a pharmaceutical facility. The units are designed to circulate hot and cold water for injection which are critical fluids throughout the facility.

CPS produced and provided to customer a model that reflected the P&ID for each of the two sanitary pumping skids. This was used to determine the actual size of the system as well as maintainability and ergonomics. This was then used internally by CPS to fabricate the system – the fabrication technicians have access to 3D models on the shop floor and use it for their daily work.

CPS supplied project management and services for:

- Mechanical, Electrical and Automation Design

- Automation Programming & Documentation

- Equipment & Instrument Purchase

- Mechanical and Electrical Fabrication

- Assembly and Tests at CPS

- FAT

CPS’ quality management system included material management & inspection, quality assurance oversight, certified test equipment records, training records, orbital welding, welder qualifications and certifications, certified weld inspection and weld documentation that were required for fabrication of the skids.

As a Rockwell integrator, CPS also provided the documentation and deliverables for the automation software scope of work. This included the following:

- Electrical design & drawings

- PLC panel – layout, I/O details

- Power

- Pneumatic design & drawings

- Sensor connections

- PLC programs

- HMI screen configuration

- Security access

- Controls sequences

- Interlocks